The right solution

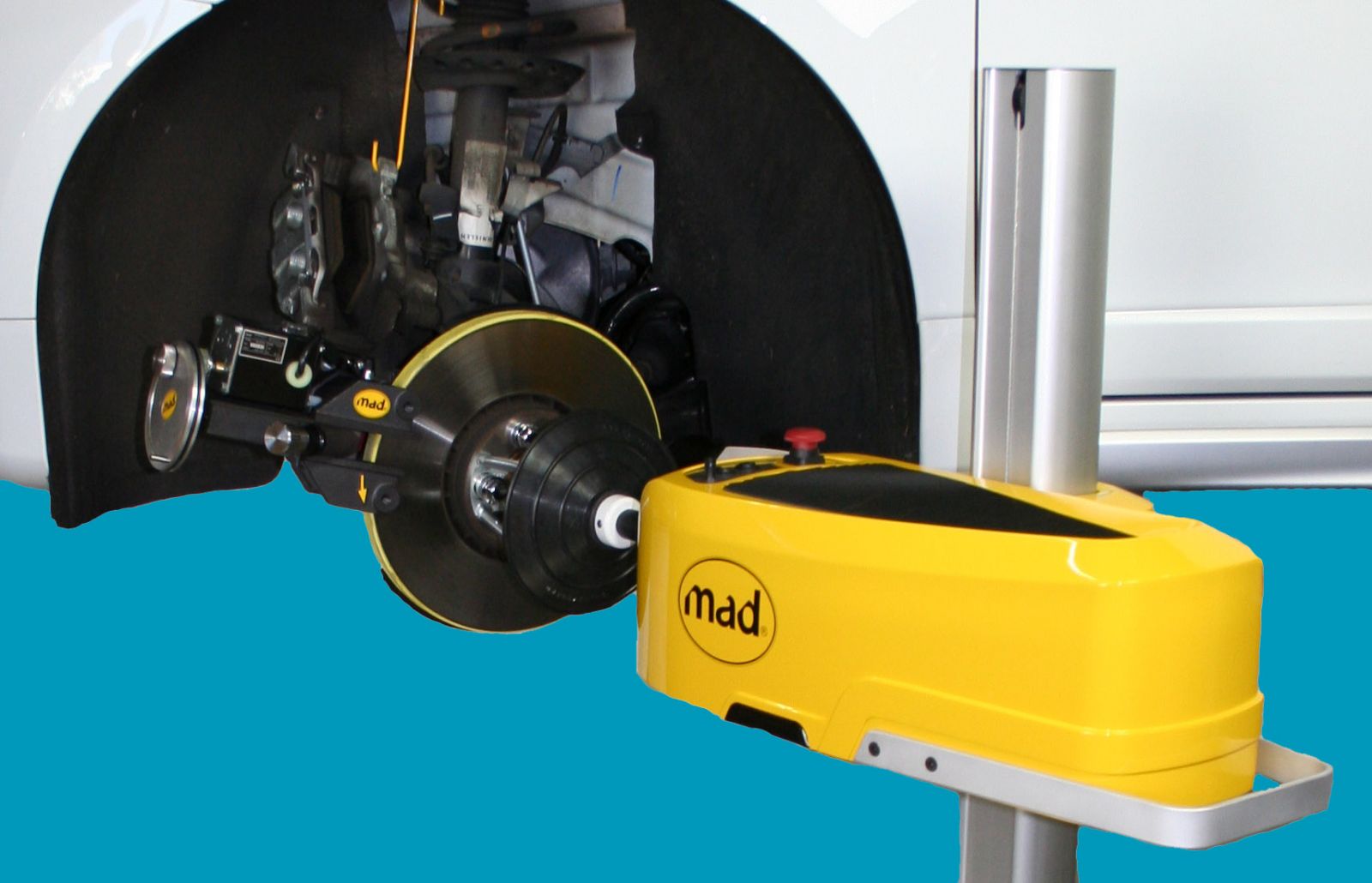

Most car manufacturers agree that the only correct method to eliminate brake problems is to realign the brake disc on the car. However, it is vital that the aligning should be done from the mounting surface of the brake calliper ears. Like its predecessor, the DA8700, the MAD DA2002 is designed in consultation with the leading car manufacturers for assembly to be done on the vehicle.

Characteristics of the MAD on the car brake lathes

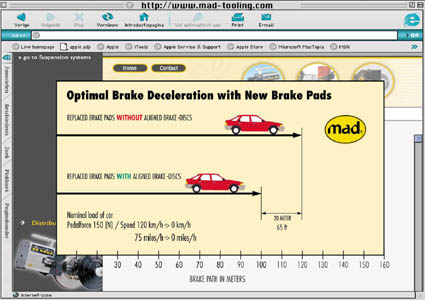

- Completely eliminates Run-out, DTV and excessive brake noise

- Saves dismantling, re-assembly and adjustment of the brake disc

- Guarantees perfect adjustment between the brake pads and brake disc

- Can be used everywhere, both on a car lift or on the ground

- Assembly on the brake calliper ears with Universal Slide Mounting

- Fits 99% of all passenger cars and light commercial vehicles, with or without ABS

The result

All brake problems solved in one action, requiring about 20 minutes for each brake disc, including dismantling and re-assembling the wheel.

The MAD brake disc aligner has been approved and often even prescribed by most car manufacturers. The savings in repair costs, and especially the long-term satisfaction of the customer, are the decisive factors in making your choice.

Advantages for your company

- Your company and all your mechanics become brake specialists

- Your customer wants "one stop shopping", that can be you

- No longer dependent on other firms for subcontracting work

- No problems in stocking parts, because you repair instead of replace

- Extra workshop turnover from car maintenance, annual inspection (TüV, MOT, RdW etc) and brake maintenance

- Accepts disc thicknesses up to 41 mm.

- Optimise the brakes of your own vehicles at a competitive price

- Long term investment without maintenance or calibration costs

- Minimum wear of parts, up to 30 alignments per tool bit, depending on the hardness of the brake disc (loss of material per brake disc adjustment: < 0,1mm.)

- Perfect result thanks to the combination of 2 speeds of the Disc Lathe with a choice of 2 speeds on the Drive Unit

- And, above all, a satisfied customer!

Quality

The MAD DA2002 complies with the strictest international test specifications for workshop equipment. The configuration has been developed and manufactured according to the ISO9001 standard. The CE quality mark is therefore a formality. Use of high quality electronic components results in a constant quality level. This guarantees a surface roughness that is often better than a new disc (< 2 µm according to DIN 4768). The MAD DA2002 carries a one year warranty, covering defective material and workmanship.

MAD works in conjunction with car manufacturers and so keeps up-to-date with all new developments. MAD's research division tests all new car types in relation to the aligning equipment.

A regular assembly summary is published for workshops that already use a MAD disc aligner. You can find these details on our web site www.mad-tooling.com. MAD supports the sale of equipment through dealers by supplying information for users. Lucid explanations and clear illustrations will persuade the customer of your expertise and the advantages of optimising the brake discs.

LIMITED SOLUTIONS

Total replacement of the brake disc

The problem lies in the interaction between the brake pads and the brake disc. Fitting a new disc is not only more expensive, but usually results in a recurrence of the problem. In addition, a slight oscillation of the hub will continue to cause vibration.

Machining the disc on a bench lathe

Apart from the extra costs of dismantling and re-assembling the brake disc and the necessity for precise adjustment, hub oscillation may continue. The Run-out cannot be eliminated.

New brake disc and brake pads

This is the only reasonable, but more expensive, alternative. When the problem will recur depends on the use of the car and external circumstances. In spite of renewal, any existing oscillation of the hub will remain to result in vibration.